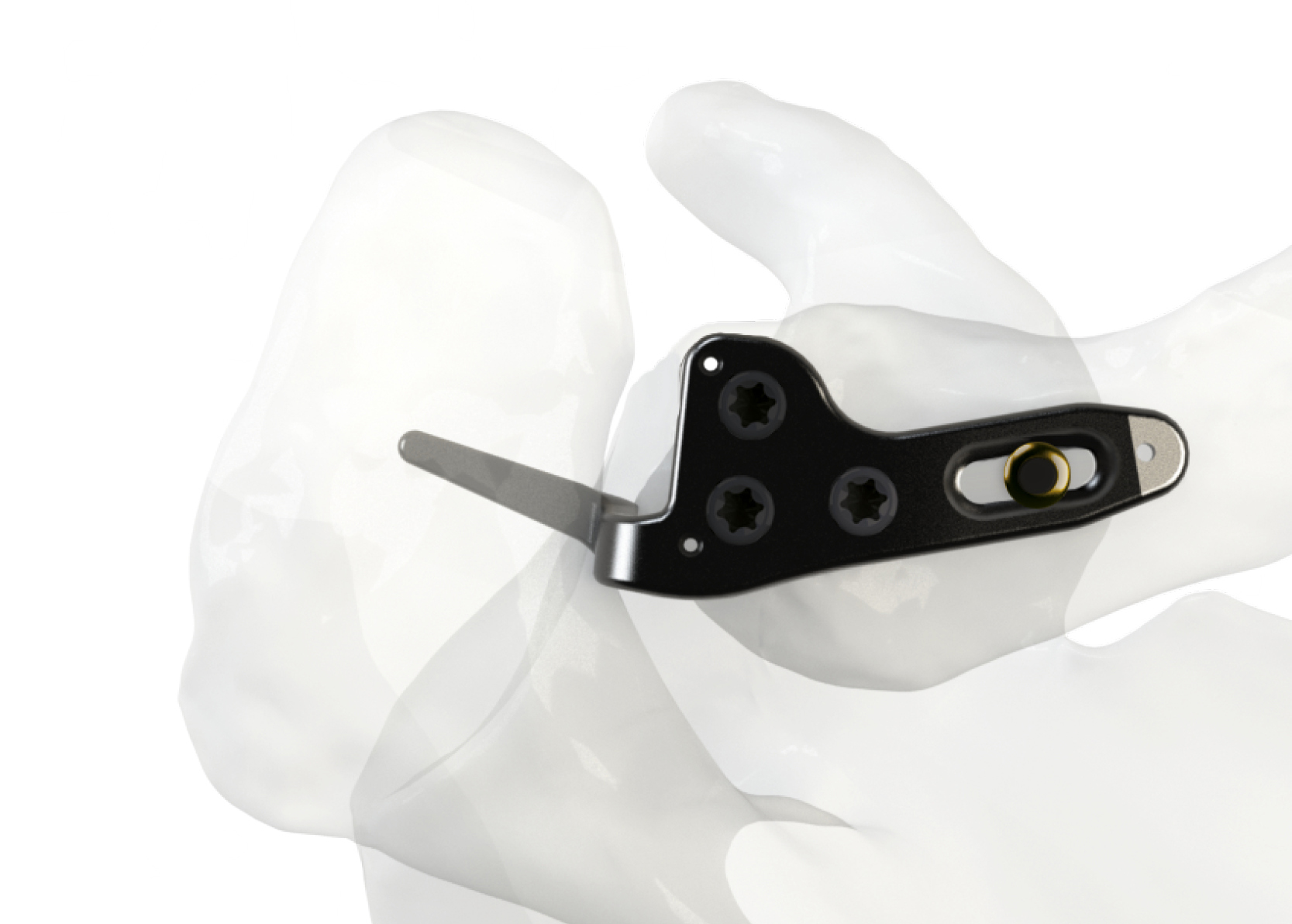

3.5mm Clavicle-Hook-Plate

for lateral fractures of the clavicle (Jaeger and Breitner), dislocations of the acromioclavicular joint and/or to secure a ligament reconstruction with an autograft in symptomatic chronic AC joint instabilities.

Surgical Technique Guide Clinical Case 1

The rounded, tapered hook design and the hook angle facilitate a biomechanically favorable position of the hook with an optimal grip under the acromion.

Rounded edges, the slim plate profile, the smooth coated surface as well as screws that sit flush on the plate reduce the risk of irritation of the surrounding soft tissue.

Rounded edges, the slim plate profile, the smooth coated surface as well as screws that sit flush on the plate reduce the risk of irritation of the surrounding soft tissue.

The anatomical plate design facilitates an optimal placement of the plate at the clavicle and the acromioclavicular joint.

Undercuts in the shaft prevent a reduced periosteal blood supply.

Undercuts in the shaft prevent a reduced periosteal blood supply.

The special surface coating of the plates and screws (Type II anodization) favours a simplified removal of the implants after fracture healing.

Dedicated Kirschner wire holes in the plate allow for temporary Kirschner wire fixation to facilitate the positioning of the plate on the bone.

Dedicated Kirschner wire holes in the plate allow for temporary Kirschner wire fixation to facilitate the positioning of the plate on the bone.

Suture holes at the lateral ends of the plate head allow additional fixation of the acromioclavicular ligament with sutures. Suture feeding is enabled through the undercuts with the plate in situ.

The polyaxial locking head screws enable multidirectional insertion at an angle up to 15° (off-axis screw angulation) in all directions and therefore provide the necessary intraoperative flexibility to individually consider particular fracture patterns.

The T15 screw drive ensures optimal force transmission, reduces the risk of deformation of the screw drive and allows for self-retention of the screw on the screwdriver.

The T15 screw drive ensures optimal force transmission, reduces the risk of deformation of the screw drive and allows for self-retention of the screw on the screwdriver.